Technical F1 Unlocked

TECH TUESDAY: Williams become the latest team to adopt a tech trend that’s set to sweep the grid

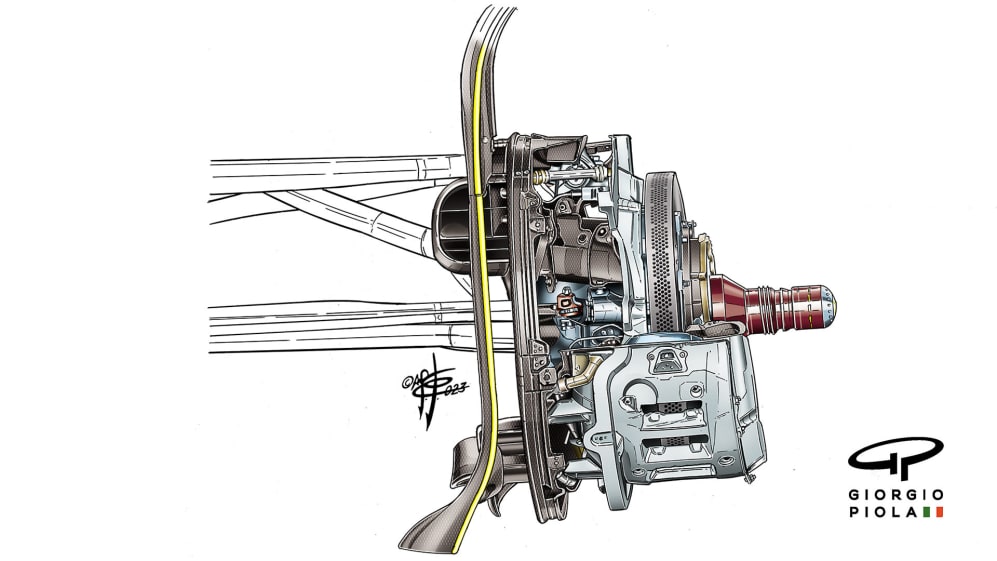

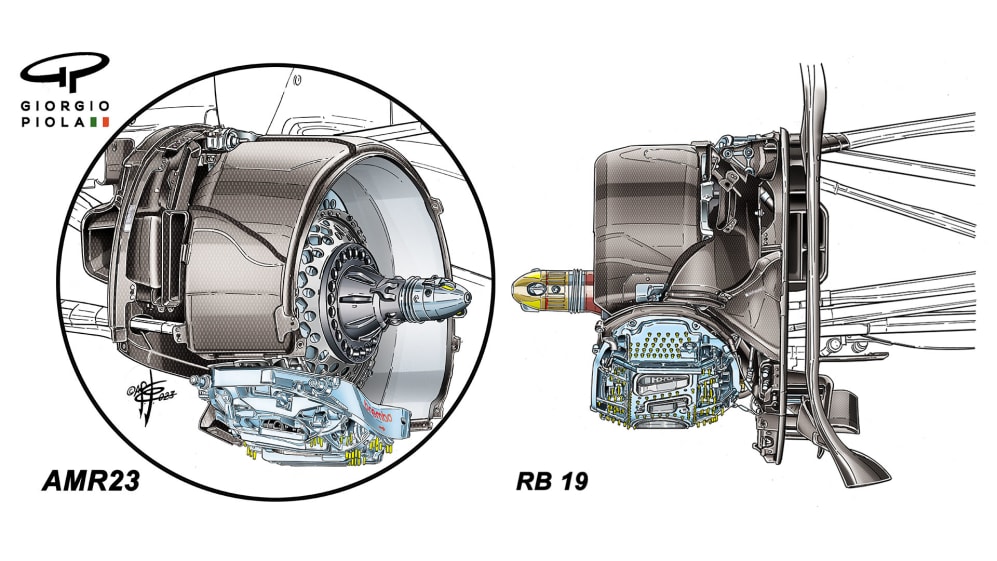

Following the lead of Aston Martin and Red Bull (as discussed here previously) Williams are the latest team to follow the trend of super-drilled brake callipers. These were introduced on the FW45 in Melbourne and were raced by both Alex Albon and Logan Sargeant.

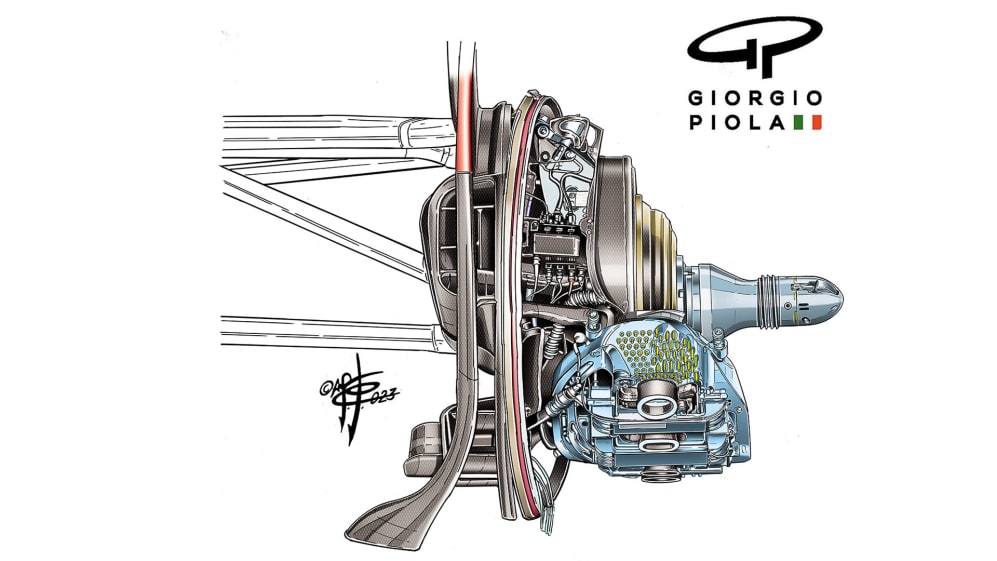

When compared to the traditional style undrilled callipers on the current Ferrari, it can be seen how much more extensively they are drilled around the area where the calliper is clamping the pads to the brake disc.

This will increase the cooling capacity for the brake disc, requiring smaller brake ducts for a given level of cooling, and therefore an aerodynamic benefit – as the front brake ducts are quite aerodynamically disruptive.

However, the fact that there is less material in that part of the calliper (because of the drilled holes) means that the calliper itself would tend to get hotter as there is less material to dissipate the heat. To combat this, there is an array of exposed pins within some of the holes, made from material with good heat conductivity, taking heat away from the body of the calliper.

These callipers save around 200 grammes per corner over the conventional undrilled component, giving a total saving of 0.8kg. Not only is that valuable in getting the car on or below the minimum weight limit, but the saving is all in un-sprung weight, which is extra valuable. Sprung weight is supported by the suspension but un-sprung masses such as the wheels and brakes have a much bigger impact upon the car’s ride and mechanical grip.

Brake callipers represent one of the few remaining areas of the car where there is still a big degree of design freedom. The manufacture of these new-style callipers is a long and expensive process.

Typically each of them takes around 20 hours to create, compared to around 12 hours for the traditional type. Special equipment has to be made to drill within the aluminium alloy of the calliper. It cannot be drilled too quickly as the heat this would create would warp the calliper and render it scrap.

Williams are only the third team to switch to incorporate this drilled/pinned calliper technology but it can be expected the others will follow.